Products > Precision Components

Electrical Contacts

MW Components is a long-time manufacturer of miniature cold-headed electronic components, including reflectors, heat sinks, electronic pins, and other miniature electronic parts.

CUSTOM MANUFACTURING

Custom Electrical Contacts

At WM, we regularly enhance our customers’ competitiveness and profitability with design improvements and value-added engineering support. For example, we have designed miniature heat sinks that combine diode heat sinks with a mounting surface, or a combination LED reflector and heat sink, and a combination of transistor heat sink and pedestal. Another example is electronic pins used with both a terminal and a reflector. In addition to our team of subject matter experts, we also provide optional tooling, prototyping, and design support.

To send us your specs or configure a part, request a custom quote.

Examples of Custom Miniature Electronics Solutions

Diode Heat Sink Button

Material: CDA 102 copper.

Manufacturing Method:

- Cold forming, multi-die forming process.

Notable Features:

- Very thin/flat shape on a wide diameter OD.

- Tapered edges on both sides (fully symmetrical) merging to a sharp point.

- Circular die mount features (both sides centrally located) are smooth, with no metal folding or pockmarks to hamper the contact surface between die and copper heat sink surface.

- Good surface finish. No machining marks or cut-off tit machining marks present.

Advantages:

- The production run rate by cold forming this high volume part is many times quicker than the machining process resulting in a lower overall cost.

- Scrap is non-existent. The competing stamping processes would need to coin this part from a scrap frame (ie: a strip of copper much larger than the part itself) resulting in waste.

Wire Bond Pin

Material: 52 alloy per ASTM f-30 (nickel/iron alloy - glass to metal seal quality).

Manufacturing Method:

- Formed on a slide machine with secondary for wire bond surface finish.

Notable Features:

- Double (identical) notches at either end.

- Very high surface finish. No machining lines or machining tit present at either end of the part on the notches.

- A very good surface finish present on the sealing surfaces. No leak paths.

Advantages:

- Surface finishes are smooth for good hermetic sealing characteristics. No machining marks/spirals/inclusions are present.

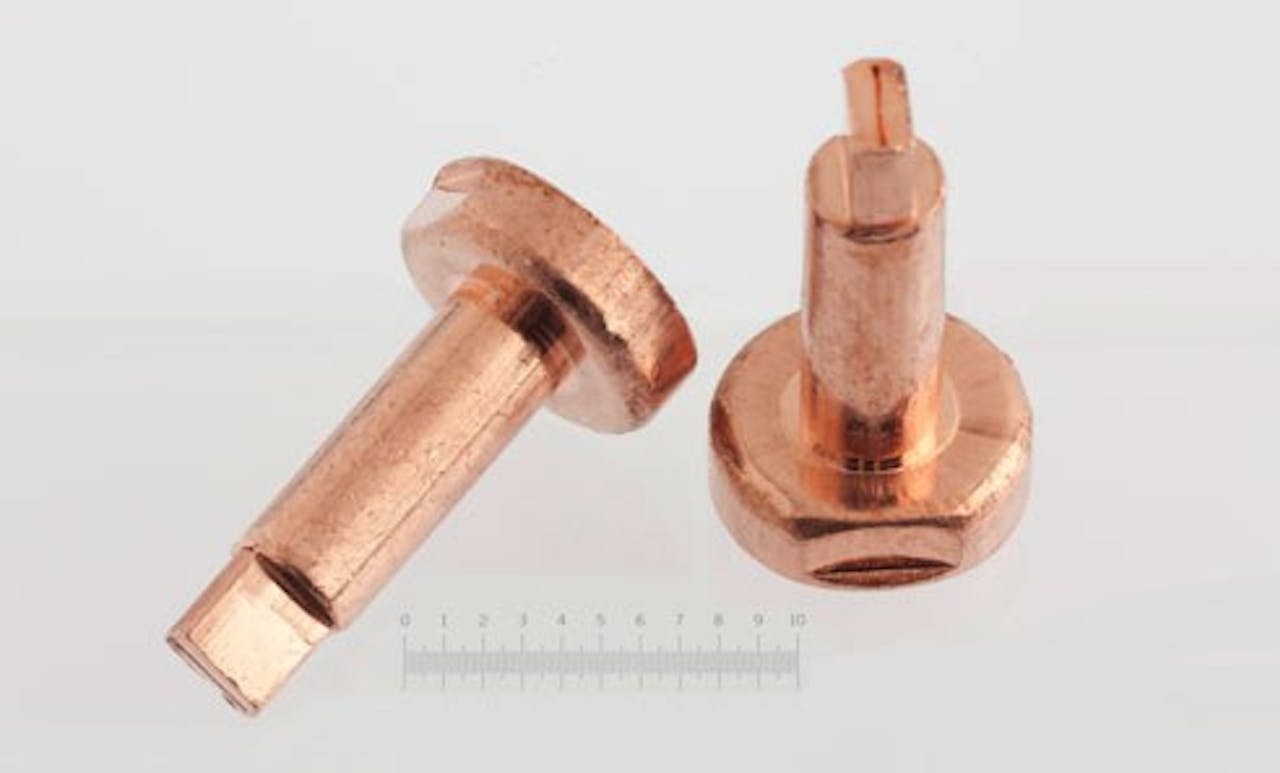

High Power Micro Wave Heat Sink Fastener

Material: CDA 102 copper (oxygen-free; high conductivity copper).

Manufacturing Method:

- All diameters plus rectangular tip formed in multi-station cold header machine.

- Thread rolling - Threaded OD formed in automatic, hopper-fed

Notable Features:

- Rectangular tip.

- Sharp cornered outside head diameter.

- Smooth top head surface (RMS 32 and better) with zero voids or inclusions or folds on the braze surface.

Advantages:

- Material waste is minimal. The part is formed from copper round wire.

- The rectangular tip is extruded from the copper blankie-no machining (no waste) or secondary used.

- Production speeds are high allowing for low production costs.

Cold Formed Diode Body

Material: CDA 102 copper (oxygen-free high conductivity copper).

Manufacturing Method:

- Produced on multi-station cold heading equipment-finished/complete off the machine.

- No secondary processes needed.

- Tools Designed in-house.

- Tools built in-house.

Notable Features:

- From top to bottom the cup contains three inside diameters, two-wire bond pads, two outside diameters, and many different wall thicknesses that vary throughout the morphology of the ring (see cross-section). No draft needed.

- The wire bond pads are very smooth with a highly polished (coined) surface finish.

- No folds developed in the part progression. Folds are sources of plating failure and separation in the field.

- Burrless.

Advantages:

- Cost. Cold forming this high volume part is vastly more efficient than trying to machine this shape. Production speeds are in excess of 80 parts per minute with minimal scrap and minimal tool wear on the crucial surface finish features (eg: the wire bond pads).

- The varying wall thickness is not easily attainable in a deep draw operation.

- This part progression has been computer simulated so as to not incorporate any metal folds in its manufacture. Metal folds can entrap oil and/or other detritus which can bleed through plating and possibly create oxidized spots at a later date.

Copper Diode Cap - Rectangular Pedestal

Material: CDA 102 oxygen-free copper/high conductivity.

Manufacturing Method:

- Multi-Die cold forming.

- Manufactured as a complete part on proprietary designed & built cold form tooling.

Notable Features:

- The rectangular pedestal used for the die mount surface.

- Large heat sink slug underneath the pedestal.

Advantages:

- Formed from wire with no scrap developed.

- Production speeds are high allowing for low production costs. Much faster than machining or grinding.

- The pedestal area isolates the die mount surface (the flat surface in the middle of the raised pedestal).

- Smooth area for die mounting.

- The rectangular feature is inexpensively cold-formed much more efficient than machining.

Diode Cup

Material: CDA 102 oxygen-free copper/high conductivity.

Manufacturing Method:

- Cold forming, multi-die forming process.

- Manufactured as a complete part on proprietary designed & built cold form tooling.

Notable Features:

- Precise knurl on OD of cup for press-fit application into an alternator bridge.

- Retention ring on the inside diameter of the wall.

- Very thin inside moat against the bottom edge/inside the wall.

Advantages:

- Formed from wire with no scrap developed.

- Production speeds are high allowing for low production costs. Much faster than machining or grinding.

- The retention feature holds tight the molded plastic.

- The moat area isolates the die mount surface (the flat surface in the middle of the cup) from the insertion forces developed when pressing the device into the alternator bridge.

- Smooth area for die mounting.

Micro Cup with Inside Pedestal

Material: 4047 aluminum.

Manufacturing Method:

- Cold forming, multi-die forming process.

Notable Features:

- .125" (3.17mm) diameter cup shape with varying wall thicknesses.

- Cup shape is formed with a precise (6 degree) outward flare within the tool progression.

- Pedestal shape incorporated into the inside bottom of the cup.

- A rare case of cold heading weldable aluminum into a complex morphology.

Advantages:

- Material waste is minimal.

- The part is formed from small diameter material and the OD features are formed up.

- No material removal is needed; scrapless. Machining methods would need to start from a large bar over 1/8" diameter and proceed with heavy material removal. Lots of scrap generated.

- Stamping/deep draw would create scrap and add to cost.

- The cold heading gives the advantage of varying the thickness of the wall throughout the morphology of the part (ie: the CROSS SECTION is able to VARY in thickness, ie: the sidewalls of the cup can be thin, the bottom can be thick, and features like the pedestal can be formed on top of the cup bottom).

- No cut-off tit issues occur with this forming process.

- The surface finish is very good. No special finishing is needed to produce a high finish. The finish is in the tools.

- The top surface of the cup walls is precisely flat to within tenths of a thousandth. This can be problematic in the stamping/deep draw process-not experienced in the cold forming method.

- Production speeds are very high allowing for low production costs, especially on higher quantity piece parts.

Square Surge Protector Component

Material: CDA 102 oxygen-free copper/high conductivity.

Manufacturing Method:

- Cold forming, multi-die forming process.

- Manufactured as a complete part on proprietary designed & built cold form tooling.

Notable Features:

- The square shape on OD & pedestals.

- Sharp corners on pedestal edges.

- Very thin morphology - not usually common for cold-formed technology.

Advantages:

- Formed from the wire. No scrap ring, no carrier strip.

- Production speeds are high allowing for low production costs. Much faster than machining or grinding.

- Pedestals on each side support die. The surface finish is smooth for die attach.

- Square shape allows for easier handling for assembly customers as well as the end customer.

Copper Cored Wire Bond Terminal

Material: Bi-metal wire: 52 alloy (nickel-iron expansion alloy per ASTM F30) with a copper core that runs through the middle of the wire diameter.

Manufacturing Method:

- Formed on a slide machine.

Notable Features:

- Copper-Core is needed to elevate the electrical conductivity of the terminal. The nickel/iron alloy will operate as an expansion alloy for sealing purposes and the small copper core will provide higher current capabilities.

- Spherical radius on one end.

- Wire bondable flat on the other end.

Advantages:

- Formed from wire with no scrap developed.

- The flat is very uniform and presents an exceptional wire bond surface. The surface finish will be integral across both the nickel/iron surface as well as the copper surface without showing any separation between the two metals.

- The corner (or edge) break at the end of the flat has a radius of .001" max. good for wire bonding near the edge of this feature-which provides a large target for bonding.

- Very good finish on the spherical radiused end. No machining lines.

Auto-Rectifier Terminal Pin with Coined C-Bend

Material: CDA 102 copper (oxygen-free; high conductivity copper).

Manufacturing Method:

- Coined & trimmed C-Bend: on a slide machine.

- Complete off the machine.

Notable Features:

- The coined area is formed into a precise C-Bend.

- A large coined area for brazing attaches to the platform.

- Smooth top head surface (RMS 32 and better); with zero voids or inclusions or folds on the braze surface.

- The flat section below the coined C-Bend.

Advantages:

- Material waste is minimal. The part is formed from copper round wire.

- The C-Bend section provides a braze platform for die attachment and the C-Curve provides give to provide stress relief.

- Production speeds are high for this high-volume piece allowing for low production costs.

- The flat area below the coined C-Bend is needed for anti-rotational stability when encased in plastic.

- The current capacity is high due to the .100\" (2.5mm) diameter wire.

- This piece is manufactured from.

Cold Formed Transistor Base

Material: CDA 102 copper.

Manufacturing Method:

- Cold forming, multi-die forming process.

Notable Features:

- Raised pedestal in a Conical Pyramid shape.

- Off-center notch and off-center pierced hole.

- Very thin, flat, hockey puck configuration.

- Good surface finish. No machining marks or cutter machining marks present.

Advantages:

- Cost. The production run rate by cold forming this part is many times quicker than the machining process, resulting in a lower overall cost.

- The density of the copper is usually higher than in a MIM process.

- This component is made from forged copper wire, not a powder form of copper.

- Good thermal dissipation, strength, and solderability/plating characteristics.

- This component is a good example showing some non-radially symmetric features usually not thought to be possible using cold forming methods.

Diode Cup Cold Formed with Pedestal in CDA 102 oxygen free copper

Material: CDA 102 oxygen-free copper/high conductivity.

Manufacturing Method:

- Cold forming, multi-die forming process.

- Manufactured as a complete part on proprietary designed & built cold form tooling.

Notable Features:

- Extremely thin wall thickness on both ends of the body.

- Raised Pedestal inside the counterbore on one end.

- Low Profile.

Advantages:

- Formed from wire with no scrap developed.

- Production speeds are high allowing for low production costs. Much faster than machining or grinding.

- Counterbore features provide for built-in containment for plastic epoxy mold material enabling the whole piece part to be made from copper enhancing heat sink capability.

- The pedestal area isolates the die mount surface (the flat surface in the middle of the raised pedestal).

- Smooth area for die mounting.

LED Diode Reflector

Material: CDA 102 oxygen-free copper/high conductivity.

Manufacturing Method:

- Cold forming, multi-die forming process.

- Manufactured as a complete part on proprietary designed & built cold form tooling.

Notable Features:

- Precise OD of Cup +/- .0003" (.0077 mm).

- The precise reflective surface on the inside diameter of the wall.

- Inside moat to accommodate a lens for light dispersion of the LED.

Advantages:

- Formed from wire with no scrap developed.

- Production speeds are high allowing for low production costs. Much faster than machining or grinding.

- Sharp/burrless corners on OD edge and onto of the reflective moat.

- Smooth area for die mounting.

Semiconductor Diode Cup

Material: CDA 102 oxygen-free copper/high conductivity.

Manufacturing Method:

- Multi-Die cold forming. Manufactured as a complete part on proprietary designed & built cold form tooling.

Notable Features:

- Wall thickness is much thicker at the bottom than the sidewalls for heat sink purposes.

- Intermittent retention barbs on the inside diameter of the wall.

Advantages:

- Formed from wire with no scrap developed.

- Production speeds are high allowing for low production costs. Much faster than machining or grinding.

- The retention feature holds tight the molded plastic.

- Smooth area for die mounting.

- The cup shape is deep due to the amount of plastic needed to fill the device.