As a leader in custom precision component manufacturing, MW Components has the right combination of manufacturing expertise and equipment, engineering and design support, and supreme customization capabilities. We offer various specialty materials and finishes, optional certifications and testing, and additional value-added services to save you time and money in production.

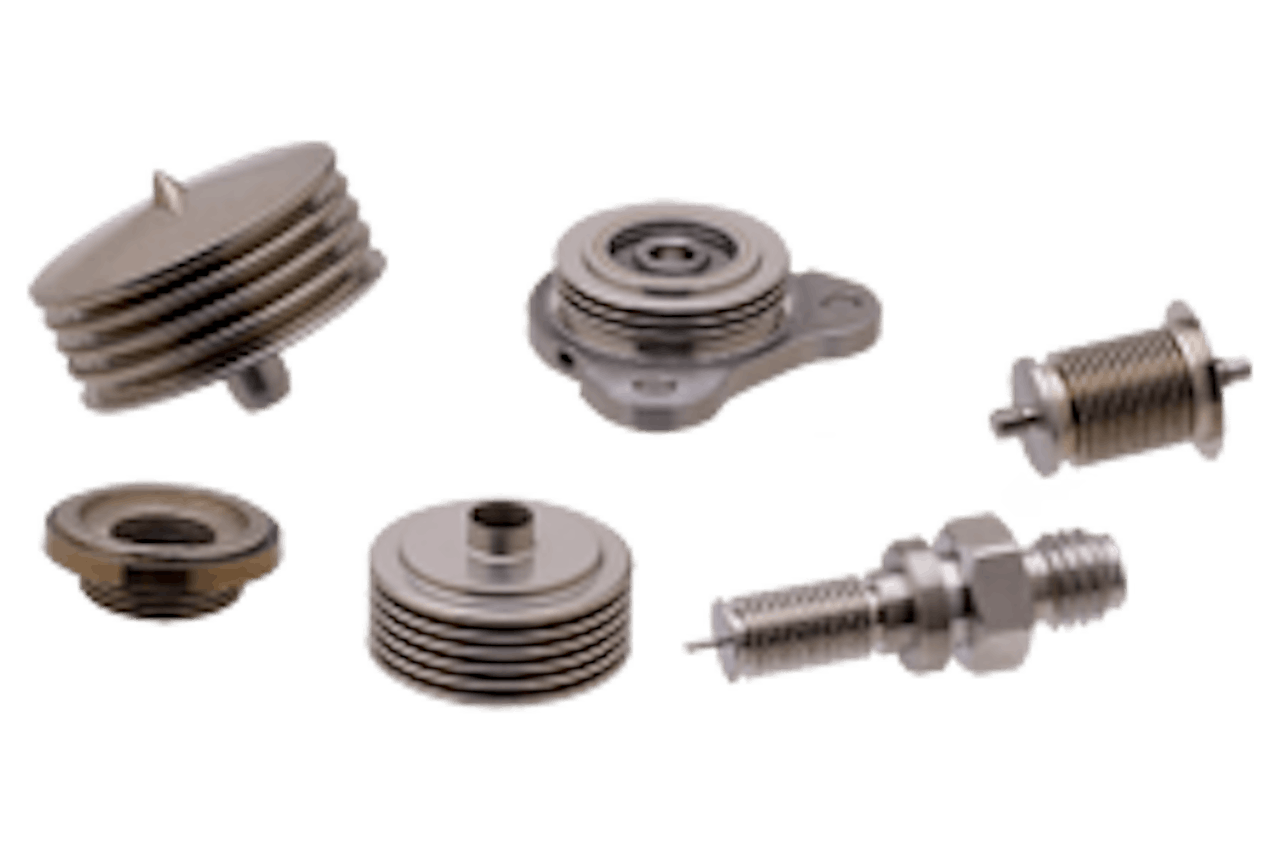

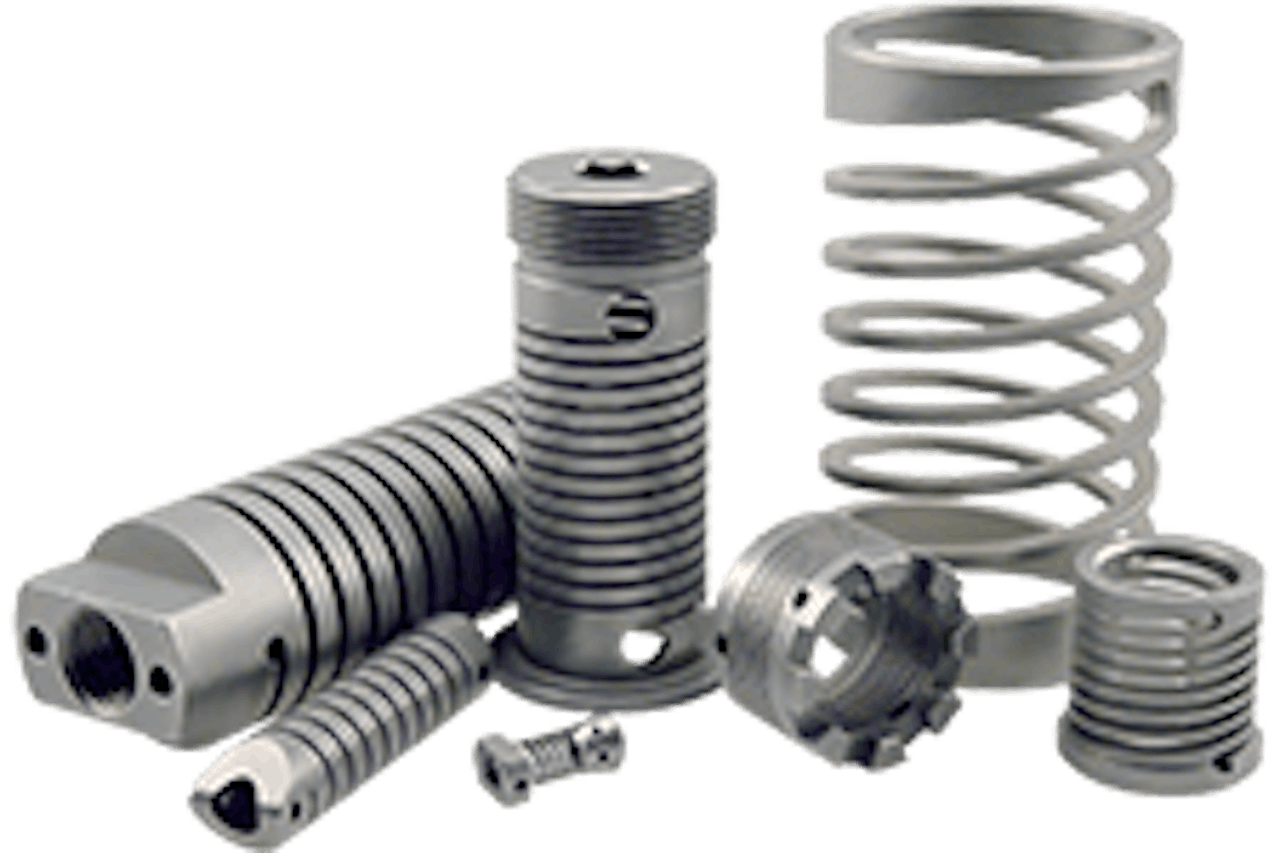

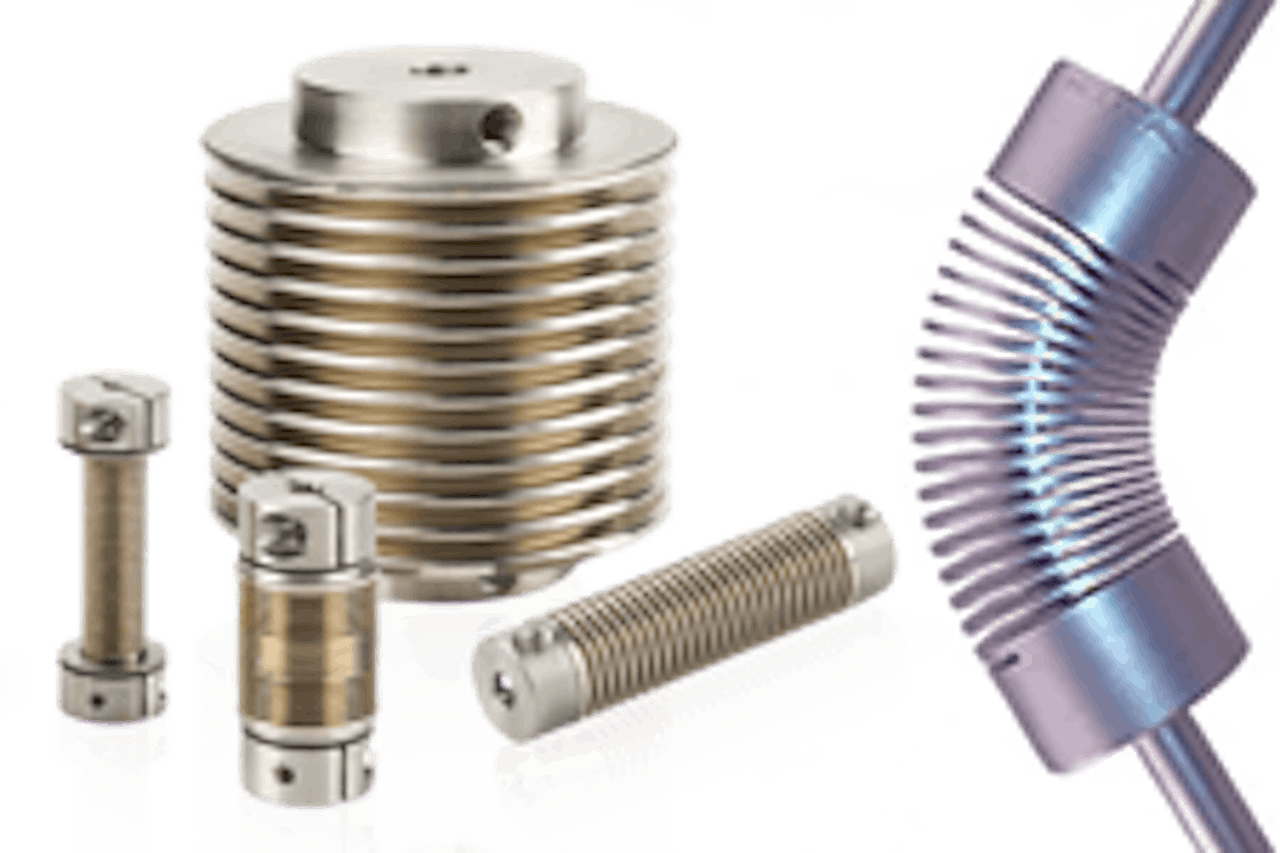

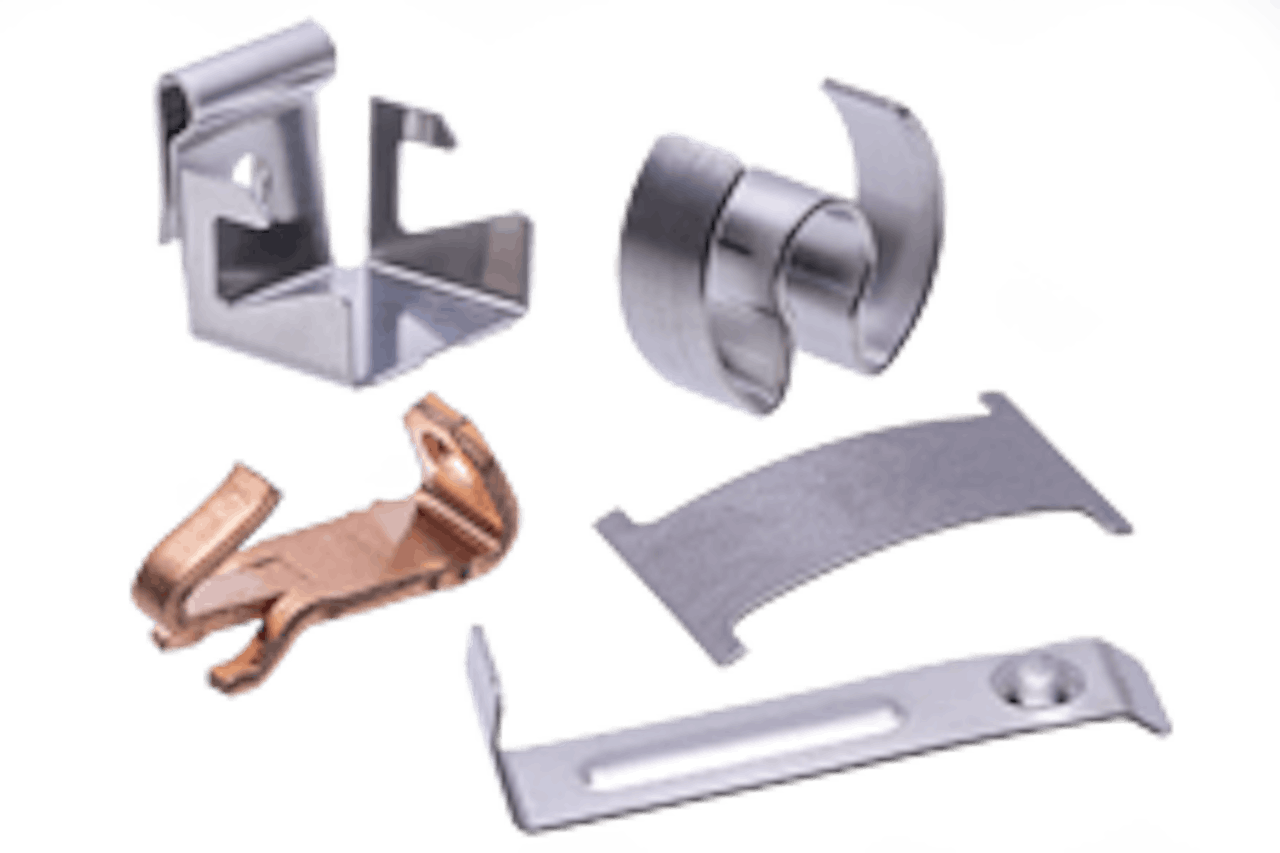

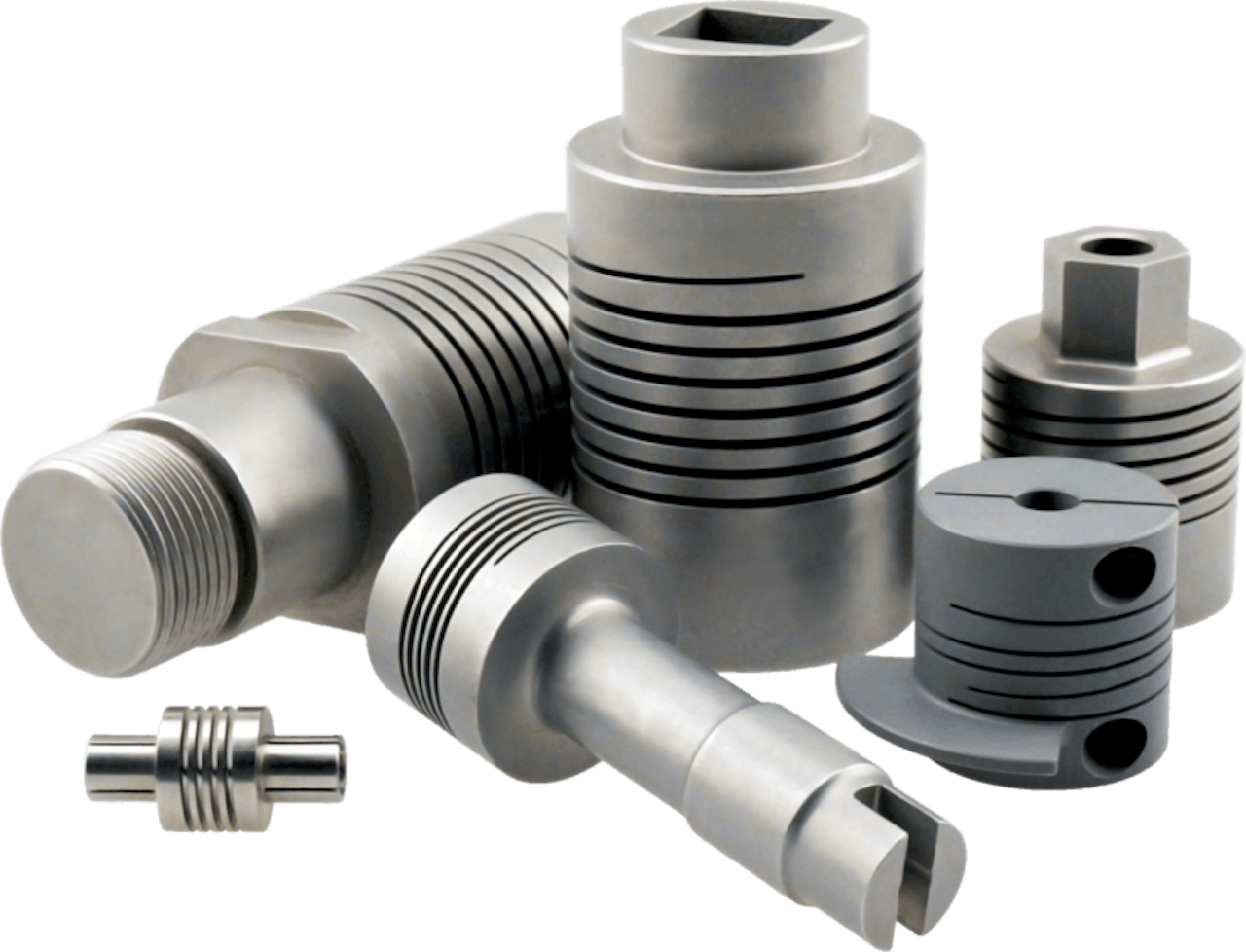

Our facilities have several quality certifications, including ISO 9001, AS9100D, Nadcap: welding, and others, to ensure the highest quality components are produced. From simpler components like shims and metal stampings to complex parts produced with intricate machining and forming technology, including metal bellows, flexible shaft couplings, machined springs, assemblies, and electroforms, MW works with you to develop precisely the component your application requires, from prototype to full production runs.

All Precision Components

CUSTOM COMPONENTS MANUFACTURER

Custom Components

MW Components locations have been leading innovation in metal component manufacturing for decades. With more than 20 locations across the United States, we are one of the most trusted US manufacturing companies for metal parts.

Our precision components locations include well-known component manufacturers like Servometer, Helical Products, Maudlin, and others. They offer a variety of custom components produced with both standard and specialty materials and plating options, as well as optional finishing processes, certifications, testing, and quality control procedures to suit your required specifications and performance needs. Request a quote for more information regarding pricing and lead times for custom manufacturing.

Our Companies

Quality You Can Trust

Made in the USA with Compliance Certifications You Can Rely On

Manufacturing Services

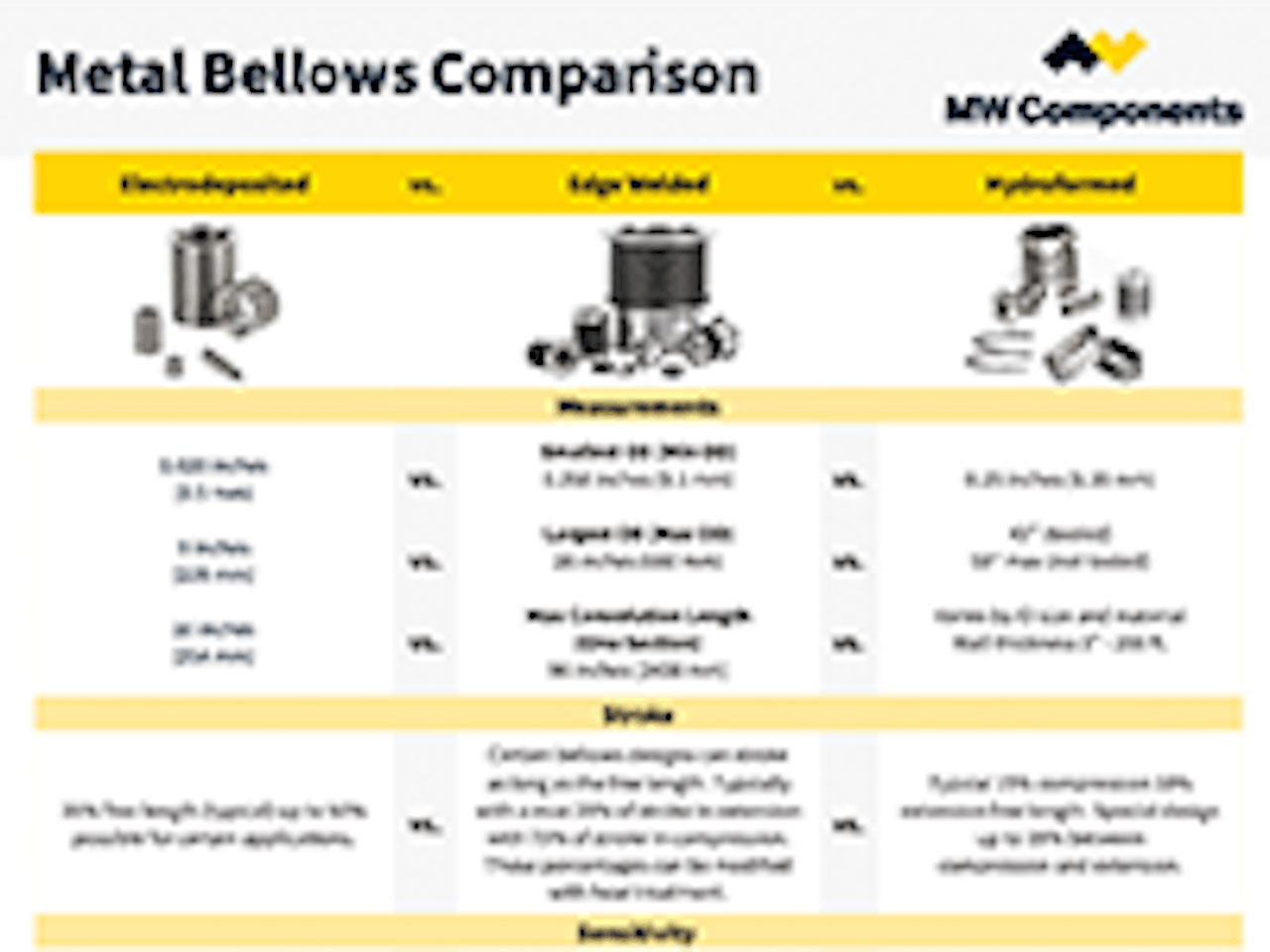

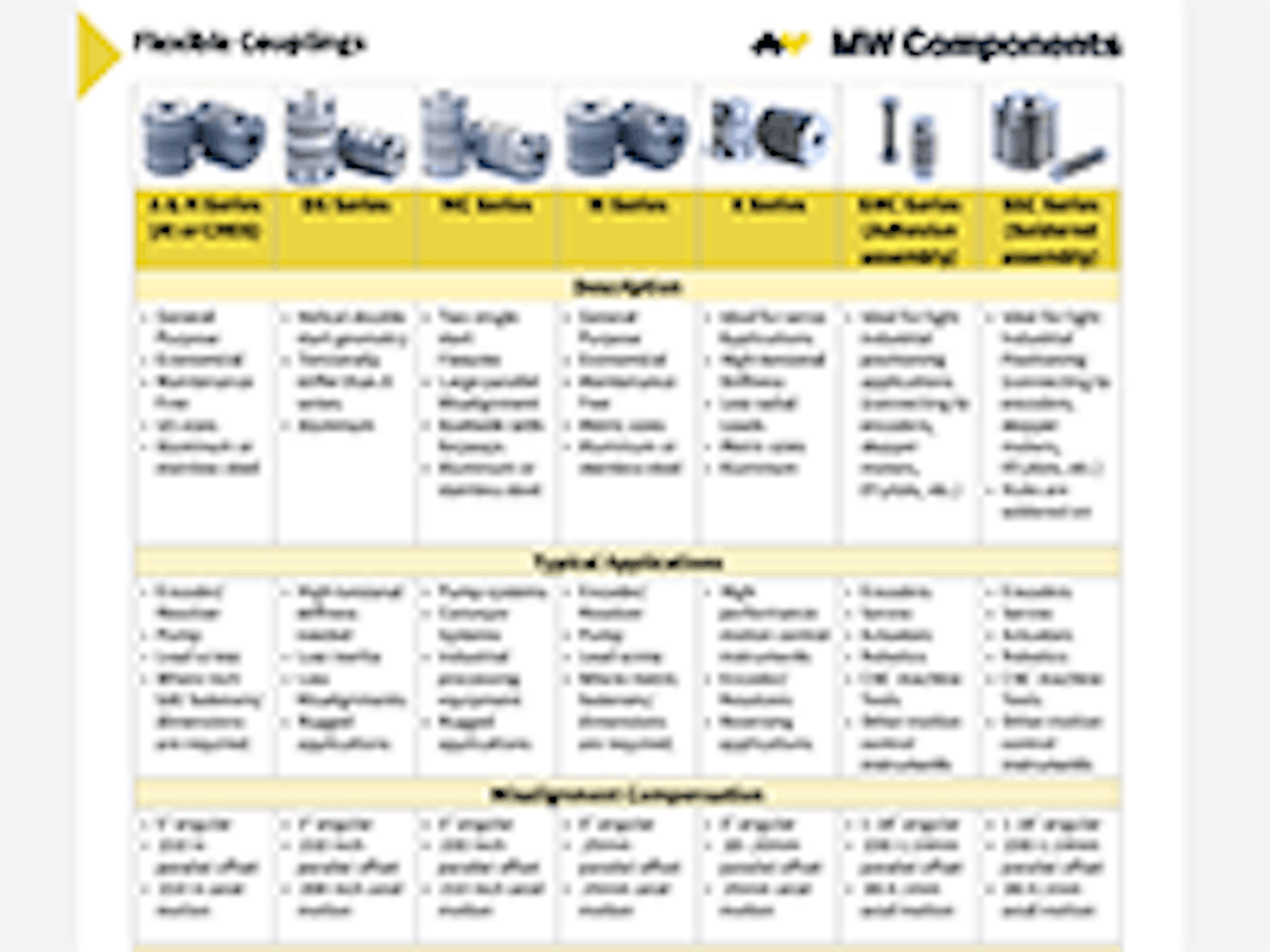

MW Components produces precision components using a variety of methods and offers several standard and specialty manufacturing and finishing techniques to ensure components are produced to your exact requirements.

Review some of our more common manufacturing and finishing processes below or view all manufacturing services offered by MW Components' precision component manufacturers.

Industry Experience

Our 100+ engineers and specialists have decades of experience designing, manufacturing, and refining the components found in many of today’s leading industries.

That's why manufacturers around the globe trust us to help with everything from component design, tooling, and prototyping including rapid prototyping, to performance analysis and virtually unlimited production runs.

Precision Components Materials

We work with nearly every metal component material available, including standard materials like steel and stainless steel to specialty alloys ideal for critical applications. Whether you need custom Elgiloy springs for oil & gas applications or FlexNickel bellows for rugged yet lightweight performance in aerospace, MW can produce precisely the part you need.

Don't see the material you need? Contact us. We can work with a wide variety of materials, including ones not listed below.

In-House Design & Engineering Support

While every custom component is different, each can benefit from the input of specialists who have developed similar parts for other industries and applications. When you partner with MW Components, you get immediate access to experts who can help you design, refine, and manufacture components to your exact requirements using decades of experience and advanced engineering software such as Master Cam, Gibbs Cam, and Solid Works. In addition, we can further support you with value-added services across tooling, prototyping, project management, quality control, and testing. This means we can help accelerate your product development cycle and shorten your time to market.

View some of our in-house engineering services below or visit our design and engineering services page to view all capabilities.

Featured Precision Components Resources

Questions about our products?

Contact us. Our sales and service professionals can help with questions regarding pricing and lead times or connect you with design engineers and manufacturing experts who can answer even the most difficult technical questions. Get in touch for questions about our products and we'll make sure you're connected with the person most qualified to help.